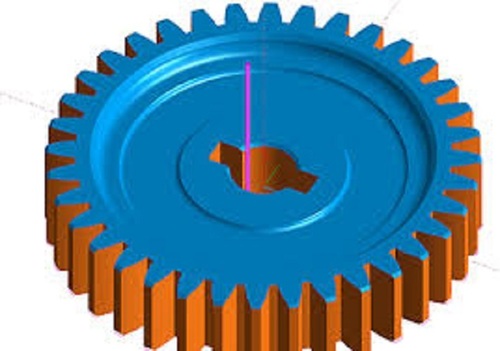

Gear Key Way Cutting Service

Price 500 INR/ Piece

MOQ : 10 Pieces

Gear Key Way Cutting Service Specification

- Keyway Width Range

- 5 mm to 40 mm

- Maximum Gear Diameter

- Up to 1200 mm

- Machine Type

- CNC Key Way Cutting Machine

- Product Name

- Gear Key Way Cutting Service

- Lead Time

- 2-4 Working Days

- Cutting Tolerance

- Up to 0.01 mm

- Finish Type

- Precision Machined

- Service Provided By

- Experienced Technicians

- Application

- Gear Manufacturing and Repair

- Surface Treatment

- Available as per Requirement

- Duration

- As per Project Requirements

- Service Mode

- Offline

- Customization

- Available

- Quality Assurance

- 100% Inspection Before Delivery

- Service Location

- All Over India

- Material Used

- Mild Steel, Carbon Steel, Alloy Steel

Gear Key Way Cutting Service Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Telegraphic Transfer (T/T)

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- wooden crate

- Main Export Market(s)

- Asia, Australia, Middle East, Africa

- Main Domestic Market

- Gujarat

About Gear Key Way Cutting Service

Comprised of team of professionals and experts, we offer reliable and value added Gear Key Way Cutting Service to our valuable clients.

Type of Service : Gear Key Way Cutting Service

Service Duration: As per work requirement

Service Mode : Offline

Service Location : Gujarat, India

Payment Term : Advance

Unmatched Precision and Quality

Our Gear Key Way Cutting Service ensures exceptional precision, achieving cutting tolerances as tight as 0.01 mm. Each component undergoes careful inspection by experienced technicians, maintaining high standards and consistent quality for gear manufacturing and repair. This meticulous approach minimizes operational downtime and guarantees long-term reliability.

Tailored Solutions for Every Requirement

Customers benefit from complete customization, from keyway dimensions to surface treatments matched to specific needs. We cater to a wide range of project demands and provide expert advice on material selection, whether using mild steel, carbon steel, or alloy steel. Our CNC machining capabilities and flexible service mode accommodate various gear-related applications across India.

FAQ's of Gear Key Way Cutting Service:

Q: How is the key way cutting process carried out for gears?

A: The key way cutting is performed using advanced CNC key way cutting machines, ensuring precise machining with tolerances up to 0.01 mm. Experienced technicians handle each project, from setup to completion, with optional surface treatments applied as required.Q: What materials are suitable for your gear key way cutting service?

A: We work with mild steel, carbon steel, and alloy steel. If you have specific material requirements for your gear manufacturing or repair project, our team can recommend suitable options and provide tailored solutions accordingly.Q: When can clients expect delivery after placing an order?

A: Typical lead time ranges from 2 to 4 working days, depending on the project's complexity and customization needs. We prioritize fast turnaround without compromising quality, with expedited options available upon request.Q: Where is your gear key way cutting service available?

A: Our services are available offline at client locations across all regions of India. We have the capacity to serve manufacturers, service providers, and suppliers regardless of their geographic location within the country.Q: What are the advantages of choosing your CNC key way cutting service?

A: Clients benefit from high-precision machining, 100% pre-delivery inspection, and flexible customization. Our process ensures durable and reliable gear components, reducing operational failures and enhancing overall equipment performance.Q: Can the service be customized for unique gear manufacturing projects?

A: Yes, customization is a core part of our offering. We adjust keyway dimensions, gear diameter, finish types, and surface treatments as per your project needs, ensuring optimal fit and functionality for your application.Q: What quality assurance measures are in place for this service?

A: Every gear undergoes thorough inspection before delivery, performed by skilled technicians. Our commitment to quality ensures your specifications are met and that the finished product performs reliably in its intended gear manufacturing or repair application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry